Trusted by thousands of DIY'ers

BUILD YOUR OWN HOLLOW WOODEN PADDLE BOARD WITH EASE

Building your dream paddle board our laser-cut Frame Kits or instantly download a set of our Digital Plans to build completely from scratch.

Let us be your guide to DIY satisfaction

How it Works

1. Glue Frame Together

Using a hot glue gun, your Frame Kit pieces are assembled and the rocker tabs are glued to your flat work surface

2. Add Wood Strips

Whether using classic cedar decking or some other light weight wood, rip your boards into manageable 1-2" strips and glue them to your frame

3. SHAPE & SAND SMOOTH

Here you can use power tools (orbital sander, planer etc.) or hand tools (block plane, hand sand) to give your board its final shape and smoothness

4. ADD COMPONENTS

Time to add a fin box, an air vent to allow your hollow board to breath, leash loop(s) to attaching your body or accessories to the board, and a handle for transporting

4. WATERPROOF WITH EPOXY

Working with fiberglass & epoxy is new for a lot of woodworkers. Don't fret, its one of the most rewarding stages as you make the wood grain pop with color and look like glass

6. RIDE WITH PRIDE

You've built your board and it's time for your maiden voyage. Enjoy paddling for years to come and share the joy of your build with others. We gaurantee you will get compliments on and off the water.

Build Your Own Hollow Wooden Paddle Board

DIY Paddle Board Models

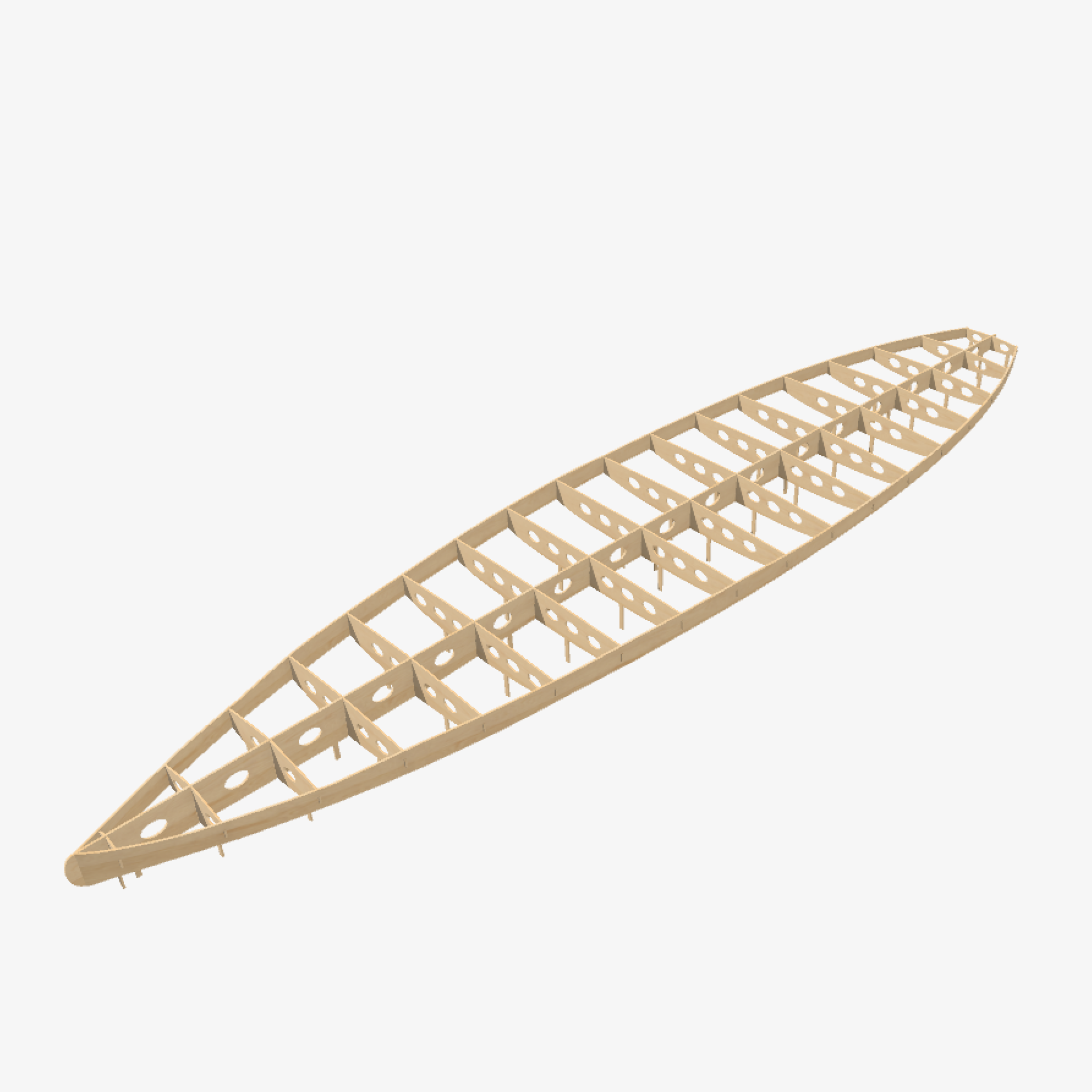

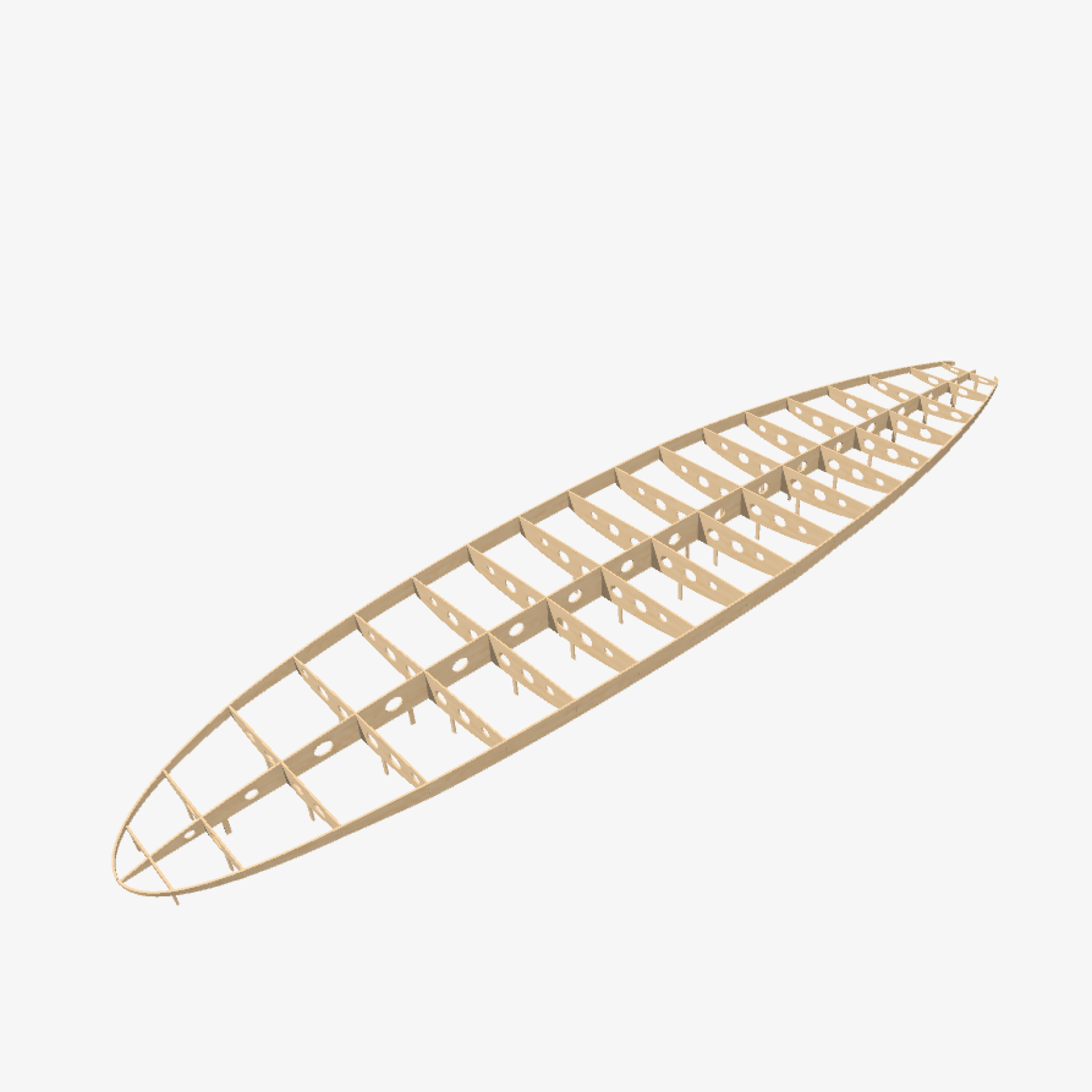

Our most popular model for a reason. This versatile standup paddle board model is designed for smooth gliding on calm waters and easy maneuvering in mild waves.

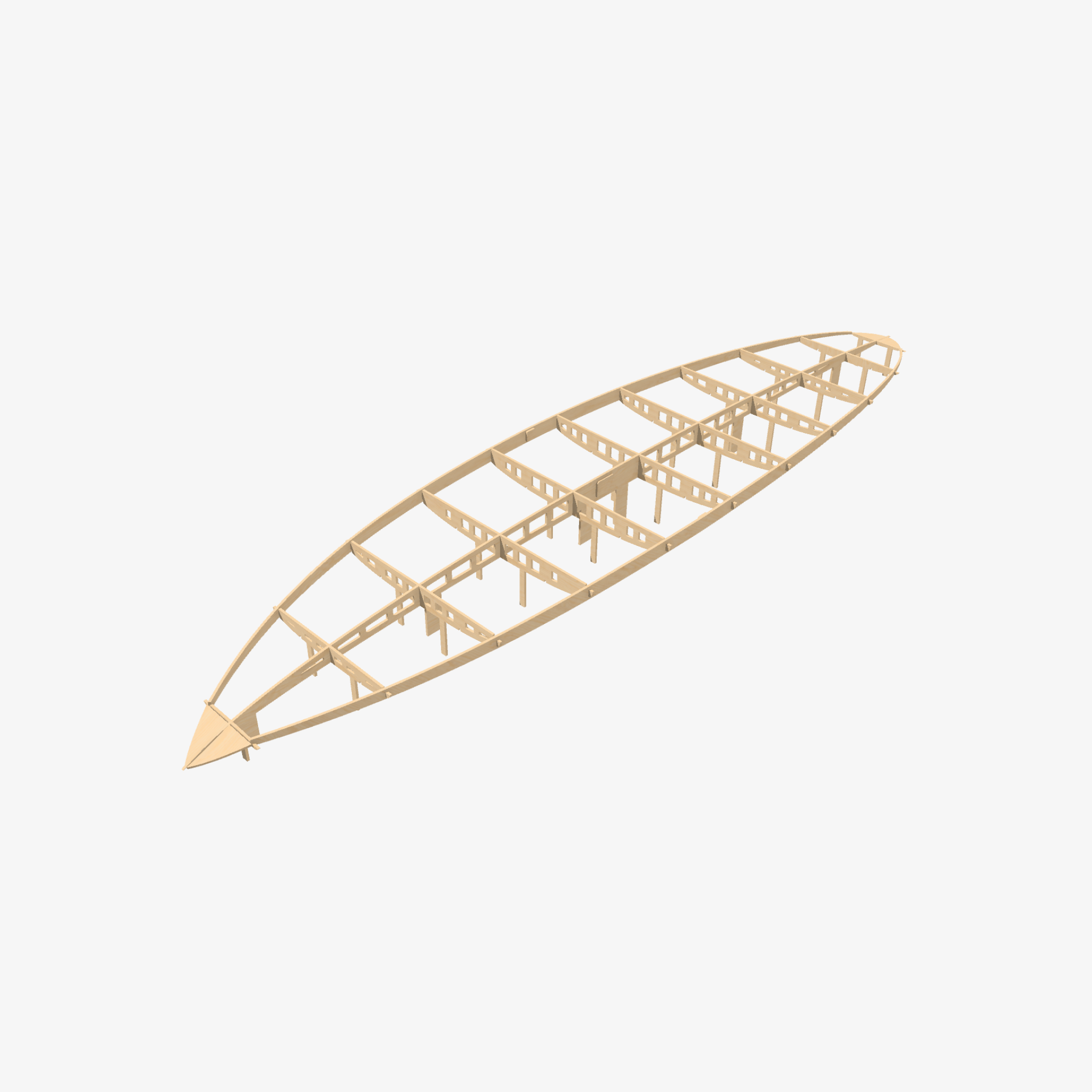

Built for speed, perfect for intermediate to advanced paddlers, this streamlined standup paddle board model features a pointed nose and displacement hull for exceptional tracking and glide on open waters.

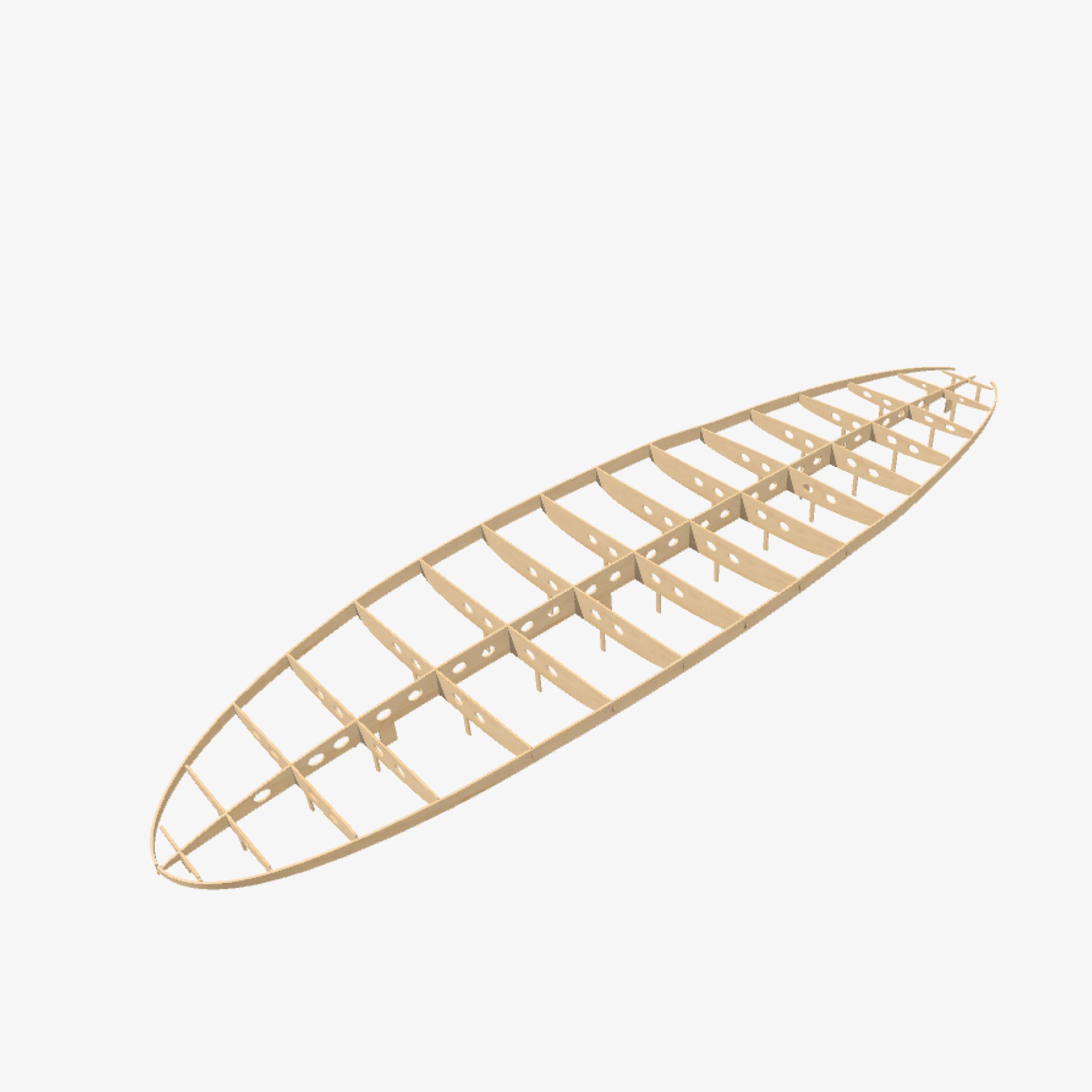

This board is perfect for riding small to medium waves. Its wide design also makes it an excellent all-around option for kids on flat water, providing a stable and forgiving platform.

About Our Kits

Beginner Friendly

Pair text with an image to focus on your chosen product, collection, or blog post. Add details on availability, style, or even provide a review.

Step-by-Step Instruction

Our detailed video & written step-by-step instructions guide you seamlessly through the process, making it accessible for first-time builders.

Materials Included

Everything you need to build a board in one convenient kit. Epoxy, fiberglass, accessories & more. We can even supply the pre-milled cedar strips if you don't want to mill your own lumber.

Precision Cut

With laser cut & numbered pieces, assembling the internal frame becomes a breeze with interlocking spine, ribs, & side rail pieces

Get Creative

Our Frame Kits provide a strong interior structure and shape, which allows you the room to build something beautiful and unique around the exterior. Get as complex or as simple as you can dream.

Community Support

Join the 1000+ board builders and share your experience and get support from this creative community

Get Inspired

See the Boards Others Have Built

Shop the Kit:

Shop the Kit:

Shop the Kit:

Shop the Kit:

"My favorite part was slowly watching it come together... and the greatest moment was when I stood on the board, it was stable and when I started paddling it tracked straight. I had done it!"

- John S. (North Carolina)

"Thank you for putting out these kits. I can't believe how well the pieces fit together."

- Jason M. (Colorado)

"I had a lot of fun with the build. I did a lot of research into build options which I spent too much time worrying about."

- Grant T. (Nova Scotia)

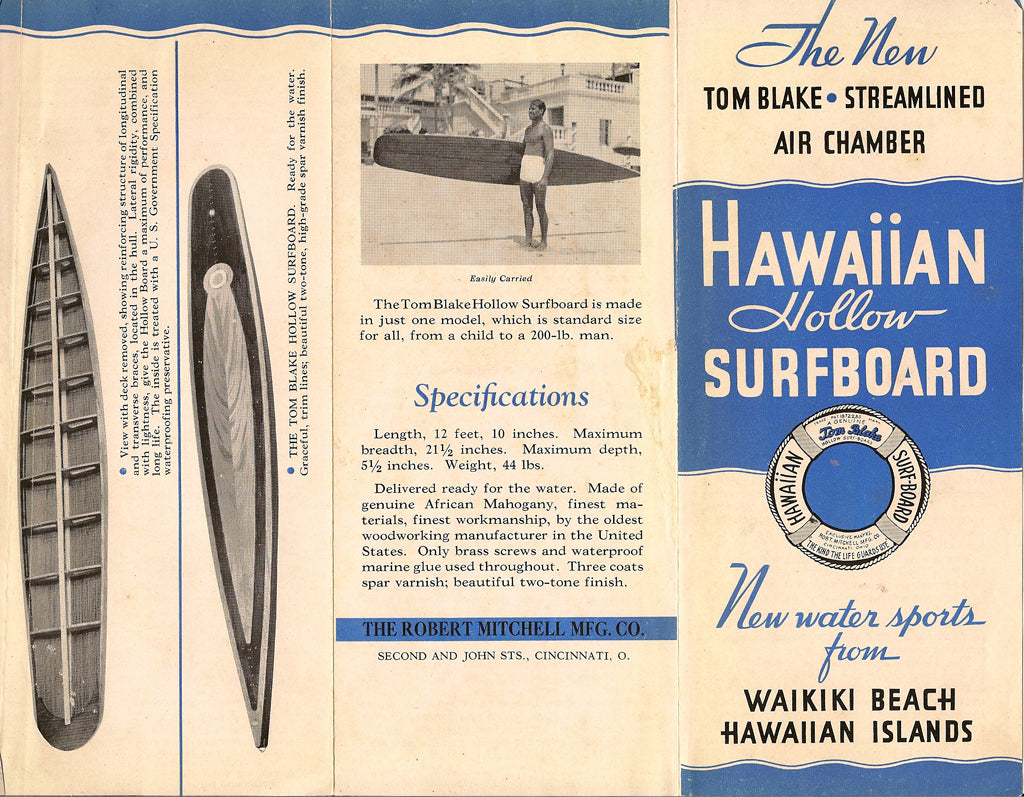

Remember Tom Blake

Join a Legacy of Innovation

In the 1930s, Tom Blake, a Milwaukee-born inventor, revolutionized surfboard design with his invention of the hollow-core wooden surfboard, replacing the heavy solid planks of the time with a lighter weight, chambered interior. This breakthrough not only made boards more maneuverable and accessible but also laid the foundation for modern surfboard innovation. Our hollow wooden paddle boards honor this rich history with a similar construction style.

Everything You Need to Get Started

Need help?

Frequently Asked Questions

Getting Started

Frame Kits include precision laser-cut wooden pieces for the internal structure, making assembly fast and easy. Digital Plans provide full-scale blueprints so you can cut your own frame parts. Both options come with step-by-step instructions.

Choosing the right board depends on how and where you plan to use it. Our All-Around SUP is the most popular option, offering a perfect balance of stability and maneuverability for flatwater paddling and mild waves. If you’re looking for speed and efficiency over long distances, the Touring SUP features a streamlined shape with a displacement hull for excellent tracking and glide. For those interested in surfing small to medium waves, the Surf & Kids SUP provides a more responsive ride and is also a great stable option for kids on flatwater

Within each board model, we offer multiple size options to accommodate different-sized paddlers, ensuring the best possible fit and performance. If you’re unsure which model or size is best for you, reach out—we’re happy to help guide your decision.

Our Frame Kits provide the precision laser-cut wooden frame, including an interlocking spine, ribs, and side rails, forming the strong internal structure of your board. Beyond the frame, we offer a "one-stop kit shop" experience on our product pages, allowing you to customize your order by selecting only the materials and add-ons you need. This includes epoxy, fiberglass, plastic accessories like fins and leash plugs, and even pre-milled cedar strips for those who want to skip the step of milling lumber themselves. Whether you need the full build package or just the essentials, you can tailor your order to fit your needs.

Yes! Our kits are uniquely designed for first-time builders, with detailed video and written instructions guiding you through every step. No prior boatbuilding or woodworking experience is necessary.

This is a multiple day project and boards take 40 to 60 hours to complete, depending on size, design complexity, and experience level. It’s a flexible project—you can work on it at your own pace, whether it’s a weekend hobby or a long-term build.

Our kits are designed to require minimal specialty tools. At a minimum, you’ll need a sander, block plane, clamps, a handsaw, and a router. If you are not using our pre-milled cedar strips, you will also need a table saw.

Ordering

Yes! We can ship Frame Kits and most components worldwide. However, some supplies like epoxy and varnish may be restricted due to shipping regulations. To save on shipping costs, you may consider starting with the Digital Plans.

Your order may arrive in multiple shipments depending on production schedules. Here’s what to expect:

Frame Kits: laser-cut to order and typically ship within 2-7 days.

Cedar Strips: Milled to order, usually ships in 1-2 weeks.

Digital Plans: Available for instant download after purchase.

Add-Ons & Accessories: Carried in inventory, usually ready-to-ship same day or next day.

Build Process

No! A flat, level surface is all you need. A simple workbench or a board across two sawhorses works great. For an inexpensive dedicated shaping table & glassing stand, check out our Multi-Function Shaping Stand plans here.

Fiberglassing is often a new skill for DIY builders, but it’s easier than you think. Our guides walk you through the process step by step. If you’re unsure, practice on scrap wood before glassing your board.

Absolutely! The beauty of these kits is that they provide a solid foundation while allowing room for personalization. You can experiment with different wood types, finishes, and design elements to make your board unique.

You will need to use lighter weight woods like cedar, redwood, paulownia, pine etc. for the majority of the exterior "skin" but many people enjoy contrasting or creating patterns with hardwoods.

Support

Yes! We offer extensive support, including detailed instructions, video guides, and a growing network of builders who share advice and experiences. You can also reach out to us directly for troubleshooting or even set up a 1:1 consultation here and we'll help you problem solve wherever you are in the process.

Next Steps

You can browse our full collection of Frame Kits and Plans here