Everything You Need To Build a Great Paddle Board

Our hollow wooden paddle board kits are designed with precision-cut internal frame structures that make the building process clear, rewarding, and beginner-friendly. Inspired by traditional boatbuilding methods like strip canoes and kayaks, each project becomes a hands-on experience you’ll be proud to paddle for years to come.

Start Your Build from One of Three Paths:

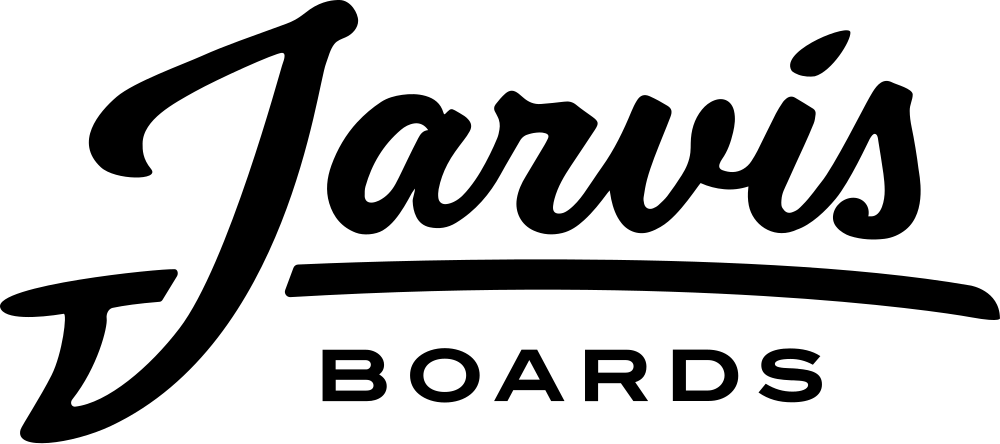

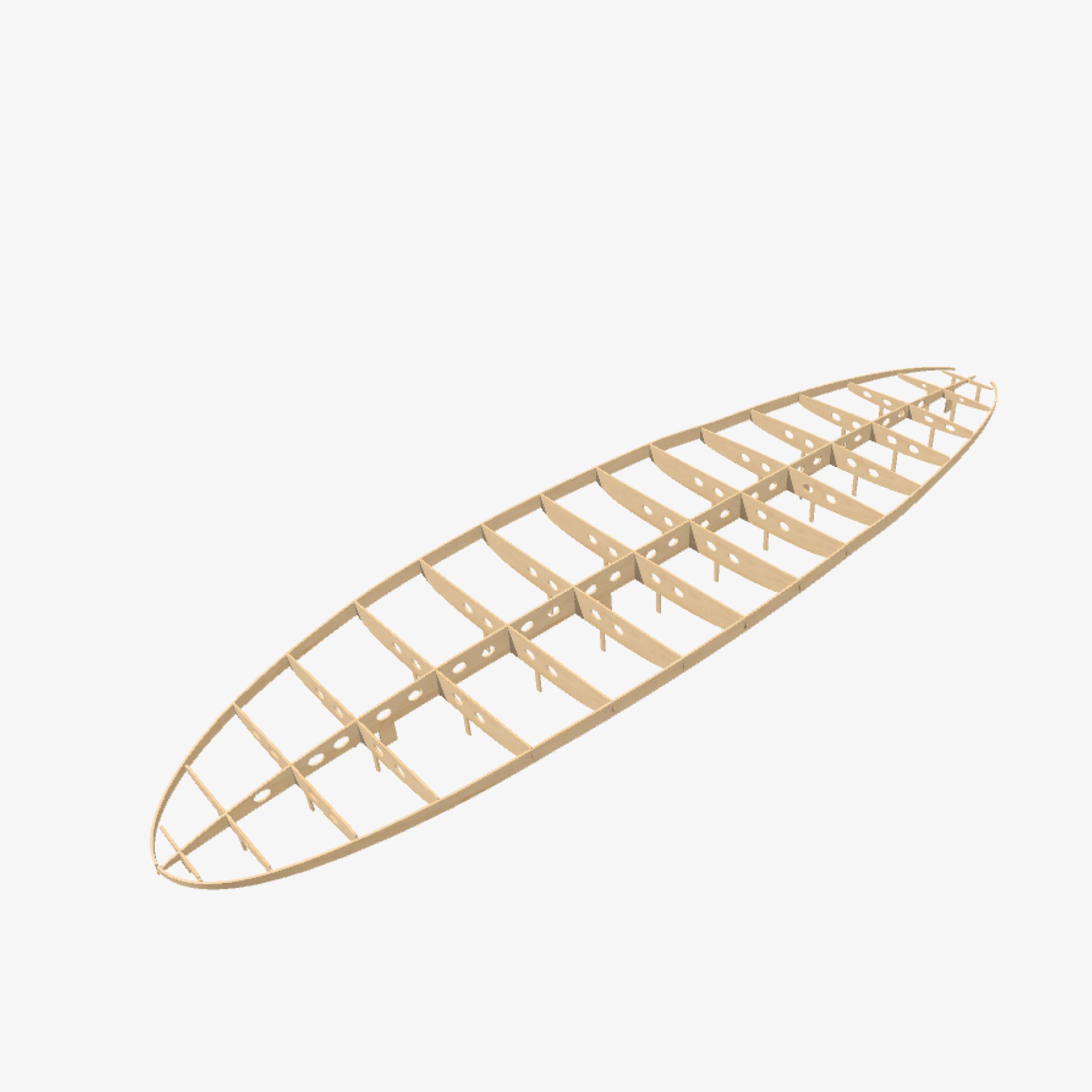

1. Frame Kit

Receive a full set of laser-cut internal ribs, spine, and side rail pieces made from premium plywood. Just add your own planks and supplies to bring it to life. Clean, simple, and highly customizable.

2. Digital or Printed Plans

Perfect for the budget-conscious DIYer who enjoys the hands-on process of cutting their own parts. Choose from instant digital downloads (ready to print on a large-format printer) or physical paper plans that we’ll ship straight to your door.

3. Complete Kit

The full package. Everything included from the Frame Kit, plus all of the the fiberglass, epoxy and components needed for building your board. Build your board from start to finish with confidence and clarity.

Choose the Right Frame Kit for Your Build

Paddle Board Sizing Guide

We offer three paddle board types to match different paddling goals, body sizes, and experience levels. Use the guide below to help choose the best fit for you:

Your Go-To Board for Everyday Adventure

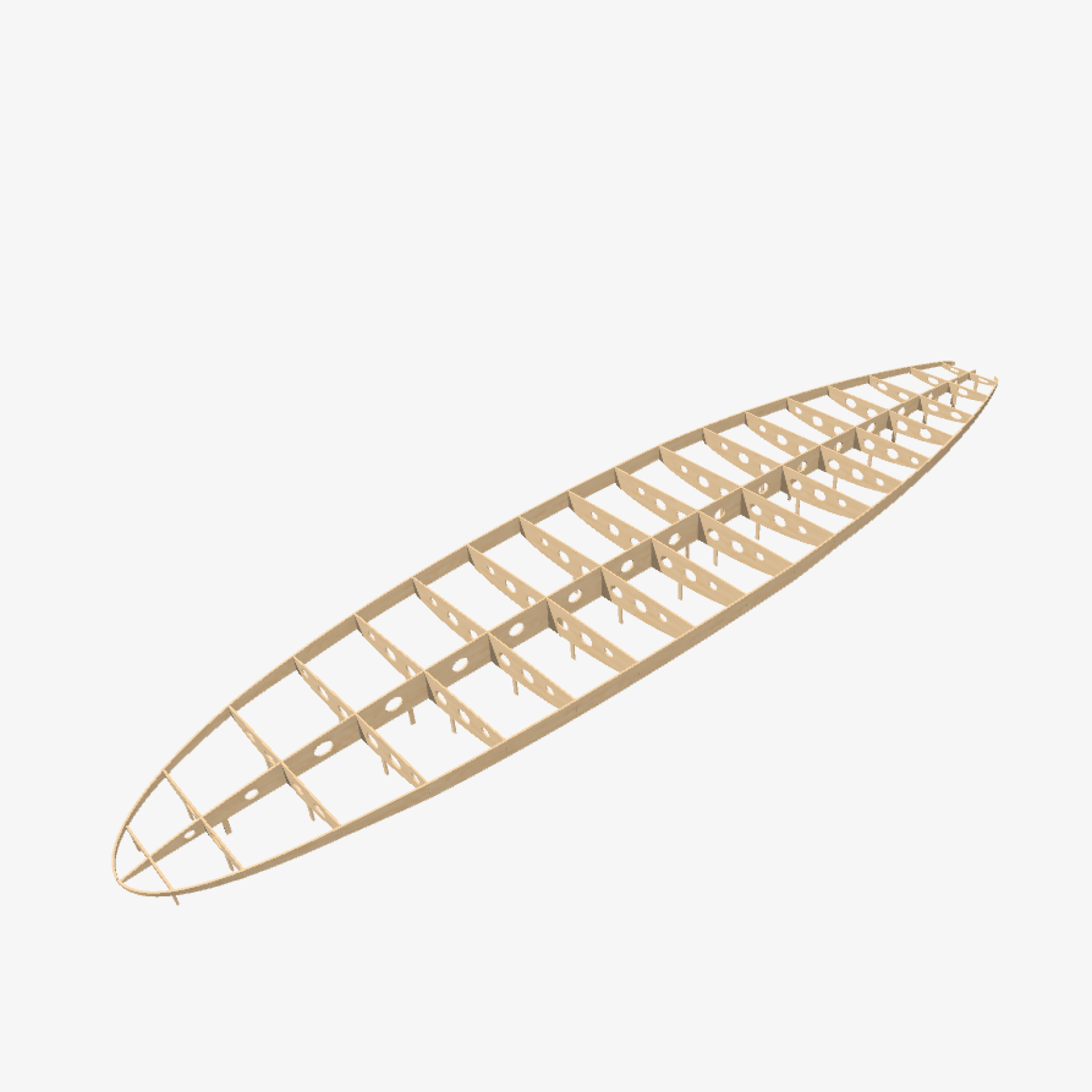

All-Around SUP

Our most versatile and most popular model, ideal for beginners and casual paddlers alike. A great balance of stability, glide, and maneuverability.

- Best For: Recreational paddling, lakes, rivers, bays

- Board Lengths: 10’4” or 11’4”

- Board Width: 31” / 32”

- Max Rider Weight: 185 lbs (10’4”) / 260 lbs (11’4”)

Fast, Smooth & Built for Distance

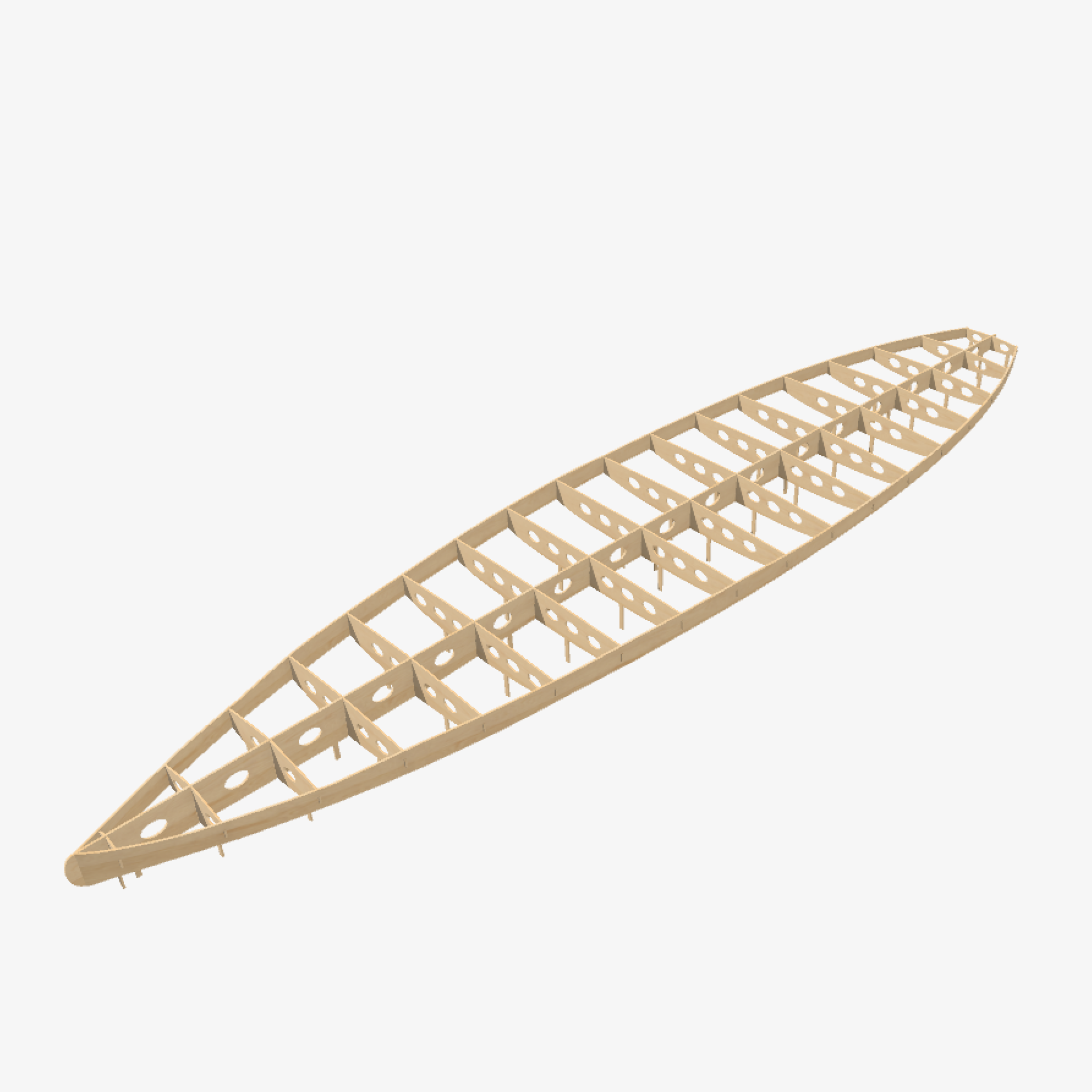

Touring SUP

Designed for those seeking performance and speed. Features a pointed displacement hull for efficient glide through the water.

- Best For: Distance paddling, fitness workouts, open water

- Board Lengths: 10’8” or 11’8”

- Max Rider Weight: 180 lbs (10’8”) / 240 lbs (11’8”)

- Board Width: 31” / 32”

Nimble & Easy to Handle

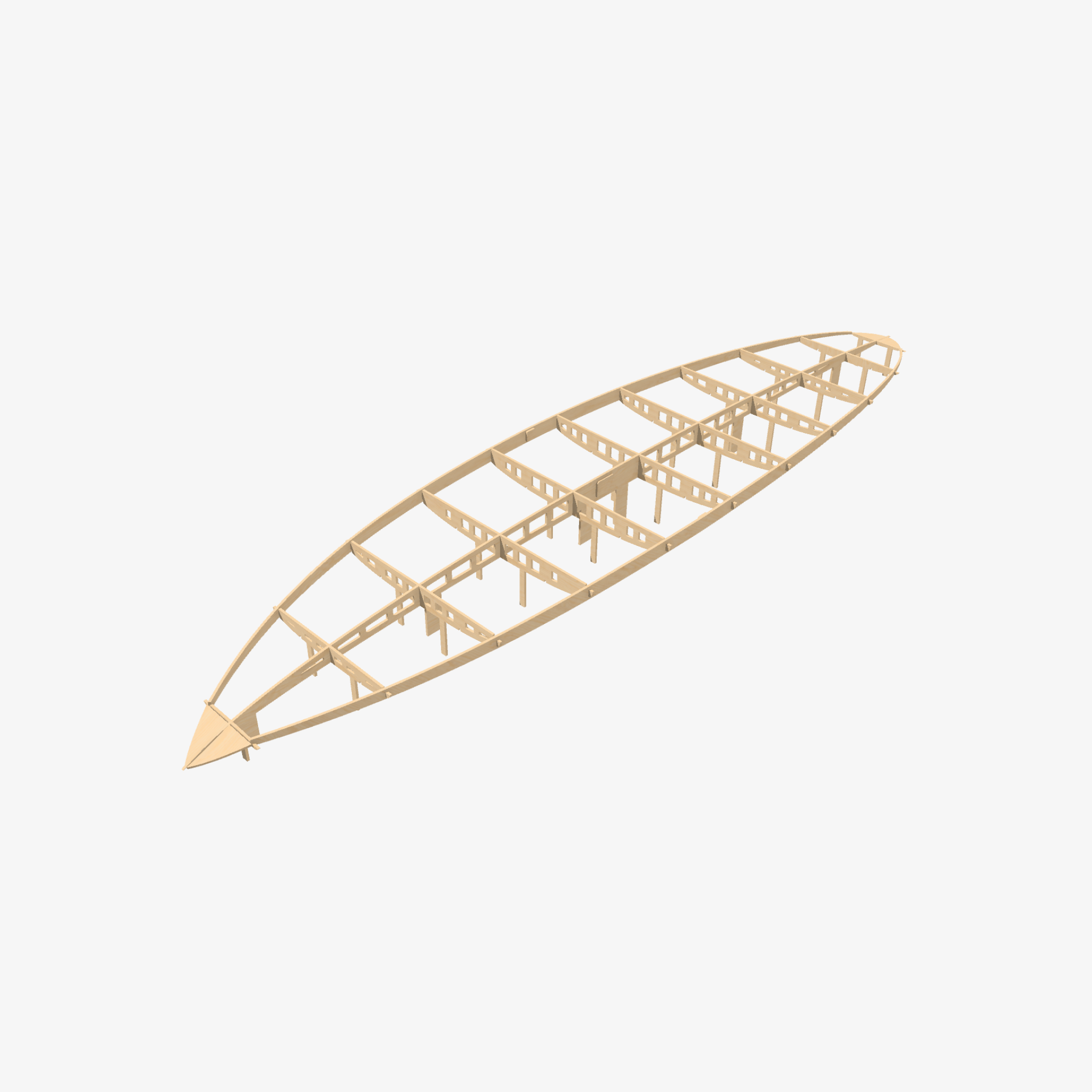

Surf / Kids SUP

A nimble, lightweight board ideal for surfing small waves or young paddlers under 200 lbs.

- Best For: Surfing, kids, petite adults

- Board Length: 9’6”

- Board Width: 32”

- Max Rider Weight: 195 lbs